[Customer Case] The Kunpeng Testing Machine was successfully delivered to the School of Materials Science and Engineering at Northeastern University, supporting materials research and achieving new breakthroughs!

Release Time:

2025-04-30 14:46

School of Materials Science and Engineering, Northeastern University Established on December 15, 2015, it was founded based on the national key discipline of the first-level discipline of Materials Science and Engineering. The Materials Science and Engineering discipline at Northeastern University was established in the early 1950s, making it one of the earliest materials disciplines in China. In the 1980s, it became a national first-level discipline doctoral degree granting point, and in 2007 it was approved as a national key discipline of the first-level discipline, covering three secondary disciplines: Materials Science, Materials Processing Engineering, and Materials Physics and Chemistry.

Based on the Materials Science and Engineering discipline, several research bases have been established, including the National Key Laboratory of Rolling Technology and Continuous Rolling Automation, the National Engineering Research Center for Advanced Steel Materials Technology, the Ministry of Education Key Laboratory of Material Anisotropy and Texture, the Ministry of Education Key Laboratory of Material Electromagnetic Process Research, and the National-Local Joint Engineering Laboratory of Electromagnetic Metallurgy Technology and Equipment. In 2014, it was selected for the national "Steel Common Technology Collaborative Innovation Center (2011 Plan)". After more than 70 years of development, this discipline has maintained its advantages in the field of metal structural materials research, while also forming distinctive features in the research fields of metal functional materials and ceramic materials.

Supporting materials research, creating new breakthroughs!

Shape Memory Alloys (SMAs) Are a class of smart materials that can "remember" and recover their original shape under specific temperature or stress conditions, with their core mechanism based on martensitic phase transformation. The most common is the nickel-titanium (Ni-Ti) alloy, which has excellent biocompatibility and superelasticity, widely used in medical stents, orthodontic archwires, aerospace folding structures, and mechanical actuators. After deformation at low temperatures, the alloy can recover its initial shape when heated above the phase transformation temperature (thermally induced memory effect), and at high temperatures, it exhibits superelasticity, automatically restoring after large deformations. Although costly and complex to process, its high energy density, silent drive, and fatigue resistance make it a key material in fields such as medicine, robotics, and seismic engineering.

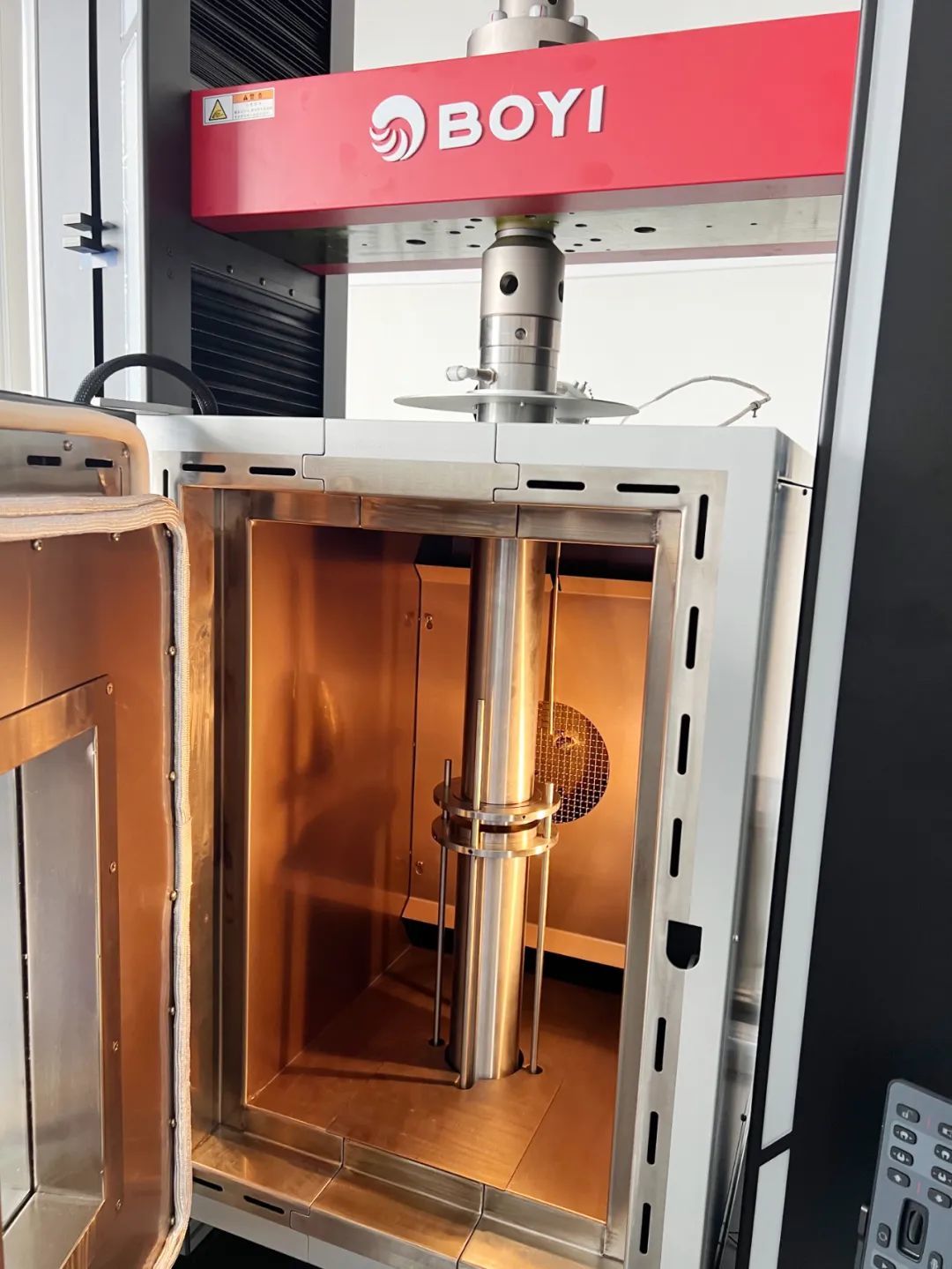

Recently, the new generation flagship product BOYI 2025-100H1 electronic universal materials testing machine, independently developed and produced by Kunpeng Instruments, was delivered for use at the School of Materials Science and Engineering, Northeastern University. With its innovative design concept, Kunpeng Testing Machine has gained increasing recognition from high-end domestic users, further validating Kunpeng Testing Machine's leading position in the domestic field of materials mechanical testing.

Recommended News

Welcome to the Testing Machine Configuration Assistance System!

Thank you for using this system.

Just answer a few questions about the test to create a test system suitable for you.

If you have multiple answers to a question, please choose the most important one.

If you have any matters to confirm, please click this button to contact us.

CONTACT US